The Impact of Innovation

In early 2022, Bigmate partnered with Coronado Global Resources to develop a groundbreaking solution in mining safety. This collaboration aimed to create the world’s first safe work Dragline Proximity Awareness System (PAS) designed to improve operator safety and eliminate blind spots in dragline operations.

- - Year: 2022

- - Partners: Bigmate, Coronado Global Resources

- - Technology Used: LiDAR, Optical Sensors, AI

- - Innovation: World-first Dragline Proximity Awareness System (PAS)

- - Objective: Reduce mining incidents and enhance safe work

- - Target Outcome: Lower operator load, enhance safe work, reduce fatalities and injuries

The Challenge

Addressing Gaps in Dragline Safety.

Mining draglines are essential for large-scale excavation, but they present significant safety risks due to limited operator visibility and blind spots. Prior to 2022, no system on the market met the required functionally safe standards for dragline operation. This gap in safety systems created a dangerous environment for operators and workers alike, with limited control over the slew mechanism and inadequate protection from potential hazards in the dragline’s extensive operating area.

Challenges:

The Solution

Bigmate’s Proximity Awareness System.

The Solution

Bigmate’s Proximity Awareness System.

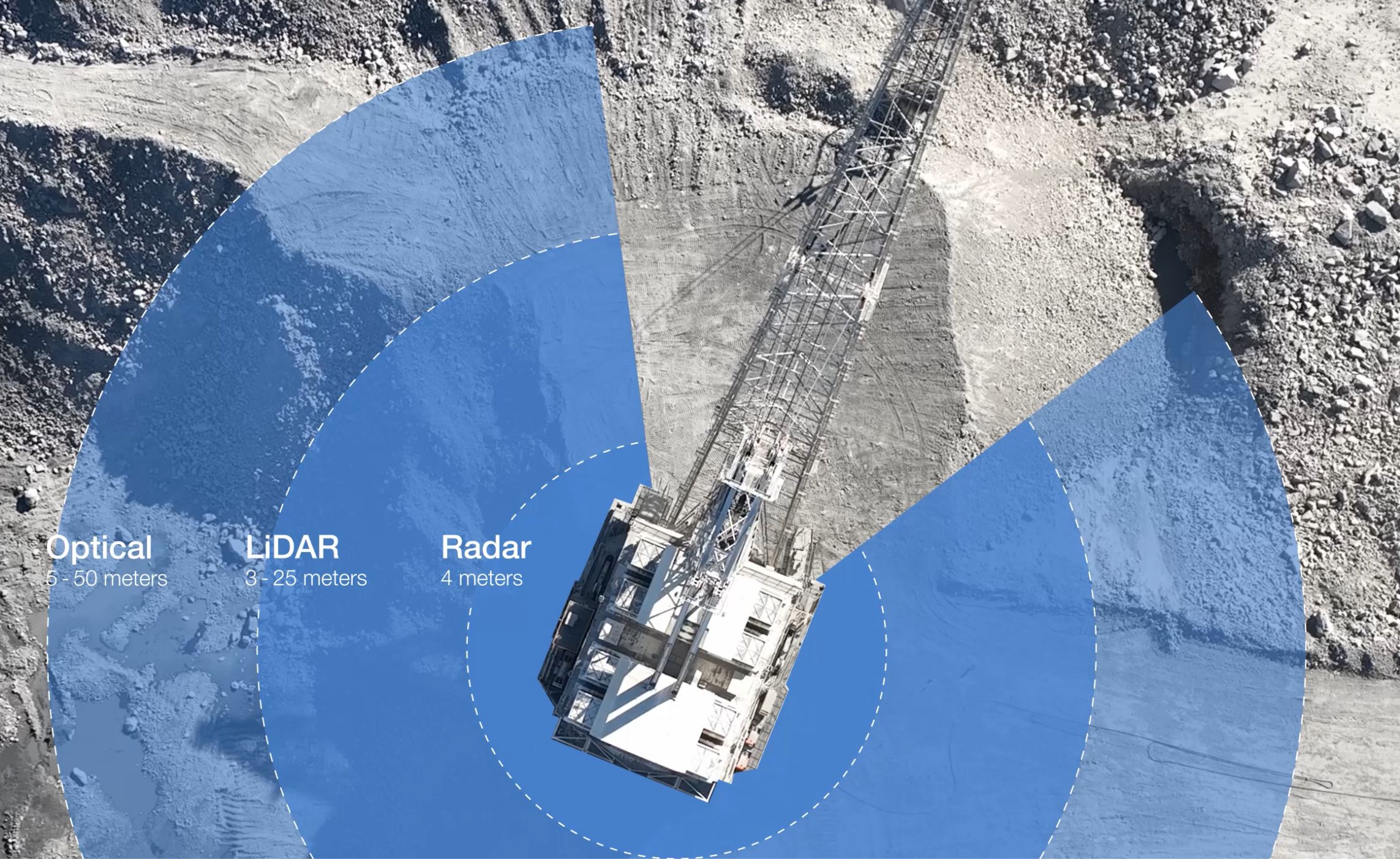

Bigmate's innovative Dragline Proximity Awareness System (PAS) was designed to address these challenges by offering 360-degree environmental awareness and automating safety controls. The system integrates two distinct sensing technologies—LiDAR and Optical sensors—powered by AI to monitor all activity within a 50-meter radius of the dragline.

Key Features of the PAS:

Overcoming

Implementation Challenges

Overcoming

Implementation Challenges

Developing and implementing the Dragline Proximity Detection System involved overcoming significant design and technical challenges, particularly the need for sensors that could cover a large area around the dragline while enduring the harsh mining environment.

The Engineering

Hurdles:

Results

Enhanced Safety and Efficiency

Since its deployment, the Dragline PAS has significantly improved safety by reducing human error and offering real-time protection against potential hazards. By eliminating blind spots and automating many of the operator's safety decisions, the system has lowered the mental load for operators, allowing them to focus on their primary task with greater confidence.

A Step Toward Safer Mining

The Dragline PAS not only addresses the immediate safety concerns but also represents a shift in the mining industry toward more autonomous, data-driven safety solutions. By eliminating blind spots and reducing the mental strain on operators, this technology offers a more effective approach to safety that could be replicated across other mining operations globally.

Conclusion

A Safer Future for Mining

The Dragline Proximity Awareness System is a pioneering safety solution that won the 2024 Queensland Mining Awards for Safety Innovation. Addressing longstanding issues in mining dragline operations. By integrating AI and advanced sensor technology, Bigmate and Coronado Global Resources have created a safer, more efficient environment for operators, setting a new standard for the mining industry, by using the Bigmate PAS.

© Bigmate 2025